“We have to solve this issue” said Mr.

Dheeraj Srivastav to the new management trainee Nikhil Kashyap while coming out

of the monthly review meeting. Dheeraj Srivastav was the HR head of Noida plant

of Cables Limited India. Nikhil Kashyap was the new management trainee hired

fresh out of a reputed management college in Noida. Increasing employee

attrition rate was the main issue in the company; in the past quarter 15 people

quit and two more resignations were on his table. This attrition rate was the

main agenda of the monthly review meeting. The board asked Dheeraj to get to

bottom of the matter and put together a report along with plans to reduce the

attrition rate before the upcoming holidays, which was in 15 days.

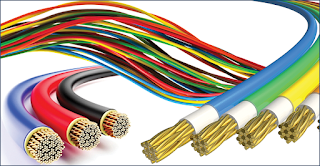

Cables Limited is one of the leading

manufacturers of power cable in India. It has a plethora of products as product

range. The company is into manufacturing of all kinds of cables, starting from

low voltage up to extra high voltage, telecom cables, submarine cables, hybrid

cables, jelly filled cables, flexible cables, instrument cables and all types

of conductors. Cables Limited was formed in 1951 with a small plant in

Thane-Mumbai. Initially it only manufactured house wires. In 1956 it acquired

India cables. In 1977 it pioneered XLPE manufacturing in India. It started

manufacturing optic cables in 1989. Like this it added many feathers to its cap

one by one and expanded the business. Now it is a 13.7-billion-dollar company.

The company is catering to customers form all background such as power sector,

oil and gas sector, Infrastructure sector, utilities sector, steel industry,

cement industry, transportation industry, and technology industry. The company

has 6 plants pan India. Noida is their state of the art facility. The 6 plants

are:

a.

Noida-NCR

b.

Mysore-Karnataka

c.

Vadodara-Gujarat

d.

Silvasa-Dadra

Nagar Haveli

e.

Howrah-West

Bengal

f.

Bhiwandi-

Maharashtra

This Noida facility is the latest feather

in the company’s cap. Prior to this there was a plant in Thane-Mumbai. But due

to high land cost and old machineries it was becoming a liability for the

company hence the company shut down the Thane plant. This Noida plant came as

the replacement of the Thane plant; the employees were moved who were willing

to. This Noida plant was a green field project. All new state of the art

machinery was used for commissioning of the plant. The plant used all

indigenous materials for construction. The company took care of local economy

by using materials, which were taken from a radius of 300 km to Noida, hence

local economy was supported to a large extent. It developed roads nearby for

better access, which gave the area uplift. Employment was done locally to

support the locals; it adopted the nearby village for CSR purpose hence the

area, which was segregated, faced huge growth and development. This main focus

of the company was to reduce carbon footprint as much as possible, it termed

the facility as green facility, which focused on recycling and reusing. The

plant had its own Sewage Treatment Plant and it used the free space to promote

cultivation growing its own vegetables to run the canteen facility. The company

received many praise for the green initiative.

The cable industry in India is a growing

industry, but the circle of companies is very small. Immerging competition and

ever lowering prices is leading the manufacturers in a price battle. The battle

to maintain quality over quantity is becoming tough day by day for the

industry. The main turmoil is keeping ethical practices and maintaining the

quality. The cable industry has some prominent names and prominent players.

Thomas Alva Edison developed the first

power distribution system in 1882; he used copper rods wrapped in jute to

transfer power. The modern-day cable, as we know it came into pictures in late

1920s. After that innovations and research led one thing to other and todays

scenario came into picture. The innovation of XLPE i.e. cross-linked

polyethylene made revolutionary change in the cable manufacturing industry,

earlier galvanized rubber was used as insulation for cables, but it had some

performance drawbacks, which could not be overcome. But this XLPE

revolutionized the cable industry as a whole and turned it over. The

performance issue, which was there for rubberized cables, was mitigated in XLPE

cables. The rubber cables had a maximum working temperature of 90°C where as

the XLPE cable had a working temperature of 120°C. When the cable works in high

voltage charged line the working temperature reaches near about 100~110°C. The

rubber cables were not adequate to handle high temperatures and hence the

voltage could not be raised after a certain extent. So, cables could not be

used to its full extent. Cables limited pioneered the use of XLPE in the year

1977. Hence the company became the pioneer of this technology and received

instantaneous admiration in India. It commissioned the first ever CCV i.e.

continuous catenary vulcanization line. So, it can be said the company had a

very good positioning in the market as per the industry.

The cable manufacturing is a complex

process, especially for the high voltage cables. This high voltage is a forte

for the Noida plant. Noida plant was set up only for production of high voltage

and extra high voltage cables. The cable manufacturing is a multiple stage

process. It starts with raw material that is aluminum or copper, steel, XLPE

for insulation, Poly vinyl chloride (PVC). The initial process starts with

drawing of copper or aluminum to form the conductor which is the main voltage

carrying material, drawing process basically is reducing the diameter of the

element copper or aluminum to the needed diameter needed. Then the drawn

copper/aluminum is layed up i.e. the single strand copper/aluminum is twisted

to form a conductor this is known as twisted stranded conductor. After this

proper conductor is made which can be used as the core element of the cable.

After conductor is made the main process starts for insulation. The earlier

mentioned CCV machine comes into picture in this process. The CCV is basically

a machine, which extrudes the XLPE material in lay, mans term it is putting of

the insulation material over the metal conductor. For this proper maintain of

temperature and pressure is to be maintained. This machine is the most

sophisticated part of the plant as well as the costliest. This machine was

imported from Germany. For this machine proper clean room is maintained i.e.

from where the XLPE is located is the cleanest and maintained room in the area.

Here only authorized personnel can enter. Because keeping the insulation

material clean is the most important job in a cable industry. If a single speck

of dust enters the extrusion process it can cause high voltage failure for the

cable. This process is very sophisticated and takes the most time in the

manufacturing process. The output of the machine is called the core. This is

the heart of the cable. After completion of the CCV process the cores are taken

to copper taping machine. In this machine copper tape is wrapped around the

core. This copper tape has different width according to the cable design and

current carrying capacity of the cable. After copper taping the cores are taken

to the laying up machine where 3 cores are assembled to form a three-core

cable. This process can take lot of time. After laying up the cable is half

manufactured. After this process the cable is given a PVC covering known as

inner sheath, which protects the parts below it. This process s also a type of

extrusion but not with the sophistication of CCV machine. The color of this

inner sheath is generally kept black. Mixing colored PVC granules to the main

white batch of the PVC changes this color. Next process is armoring. In this

process depending upon the design the strips or rods are put over the cable

assembly to protect it form external environment. This layer has no electric

advantage or work but is an integral part because it is the protection for the

cable. As a safety this armor is also grounded at the time of termination of

cable, gives extra electrical safety to the cable. The final process of the

cable manufacturing is outer sheathing. In this process a thick PVC layer

covers the cable. This layer is known as outer sheath and is the final surface

of the cable. The color of this layer is made as per requirement and design.

Colored PVC granules are mixed with the white ones to get the required color.

The final step after the manufacturing process is testing of the cable. All

manufactured cable goes through routine test to check the performance of the

cable and quality of the cable before dispatching it to the customer. This

whole process of manufacturing takes around two to three days.

Cables limited has different types of

employees on direct and indirect payroll of the company. To categorize first

there is the management staff, which are on direct company pay roles. Then

there is a concept of HPTs (High performance teams) and finally there are the

labors. HPT is the new concept, which is brought to the industry by this

company. In this concept people age of eighteen or more is hired from the local

employment centers. These people are chosen from humble background to generate

employment to the local areas. These people are tested on various level and

finally a psych evaluation is done before hiring. These HPTs are then given

proper accommodation and food service from company. They are supposed to work

from Monday to Friday and they pursue a diploma degree in the cable

manufacturing process, along with the company pays them salary. This HPT

concept is a concept, which is very innovative, and the company received lot of

praise from the industry and media. This type of CSR event is bringing the

company to different level of accomplishment.

Afterwards we come to the management

staff, this hiring process is very stringent and follows well-defined steps.

The company has a policy to hire form the top colleges of the nation for

graduate and management level entries. People who are hired into managerial

level and higher goes through the same type of stringent process, all the

process are very stringent and the company chooses from best of the lot. In the

year 2014 the company received the best place to work award in the industry.

Anjan

Dutta is the vice president of the company who is accounted as the plant head

also. Under vice president comes the sectional managers or the head of the

departments each of production department, quality department, finance

department, procurement department, human resource department, maintenance

department and design department. Under the head of departments comes various

manager and assistant managers; under these managers comes the senior

engineers. Below in the hierarchy tree comes the engineers. HPTs reports to the

engineers. These HPTs controls and guides the labors. Refer exhibit 1 for the

organizational structure. The graduate trainees are hired into GET post and

they are promoted to engineer level in one year as per their performance. After

wards the engineers become senior engineer based on the performance ratings and

their caliber. This chain continues till the manager level. HPTs have well-structured

promotional level. By years of experience and skill level they are graded and

promoted in grades. After completing 5 grades they are made into engineers. We

can see that the company has well defined organizational structure.

Dheeraj

was concerned about the increasing attrition rate. As per the general

observation the main problem centric area was HPTs and Engineers, the bottom of

the chain. This needed proper investigation. Dheeraj gave the Nikhil who is a

fresh management trainee human resource trainee to work out the details of the

departments in which the maximum attrition came from. Dheeraj also did a survey

on job satisfaction level. As per Nikhils findings the most of the attrition

came from Engineering levels and HPT level. The engineers from different

departments were leaving their jobs. It was with the HPTs. The most affected

verticals were production vertical and quality vertical. The main issue was to be found out why these

two verticals and the bottom chain is getting affected.

The job satisfaction survey, which was

performed with the consent of Dheeraj, yielded alarming results. The analysis

shows the main cause, which was being reflected, was due to lack of proper

communication and issues over proper timely promotions. The labors who were the

ground zero of the company was employed by from local areas. The contract for

hiring labors was given to a third party. The labors were given two forty

rupees per day as a wage by the third party which was in charge of providing labors.

The Labor provider provider or the third party billed the company on a monthly

basis. The labors were supposed to work eight hours a day. The Labor provider

had a policy of over time. If the labor works more than eight hours a day

labors will be provided with over time wage. If it is considered the labor gets

two hundred forty for eight hours then his hourly wage is thirty rupees. Labors

received double the pay after normal depicted hours. That is the labors

received sixty rupees per hour for as many hours they worked after the

designated eight hours. The company ran for twenty-four seven and three shifts

a day. To maximize profit and gains the normal practice by the labors were to

work for sixteen hours straight to increase their daily earning. The labors

needed money, as maximum were farmers. This sixteen hours work led to less

efficient work completed. This was the main cause behind all the problems. As

based on this all the issues started. Due to less efficient workers the HPTs

could not supervise properly as they were also busy in scheduling works to most

of the efficient labors. In the company there was a policy of conducting shift

meetings in which daily works were distributed and targets were defined. Due to

less efficient labors the HPTs could not complete the daily targets. Which led

to arguments with the engineers because if the HPTs did not complete their

targets that affected the targets of the engineers or senior engineers. This

led to heated arguments and discussions, which was the main issue of the job

dissatisfactions. If the targets were not met regularly then it affected the

performance evaluation and appraisal process, which led to less promotion, or

incentive hikes. The employee morale was decreasing day by day and every one

had the notion to leave their jobs. The main attrition was visible and

prominent in the lower ranks because it was totally dependent on the meeting of

production targets. As the corporate ladder is climbed then there come various

factors which affect the appraisal system. Then there was this issue why the

only production department and quality department was getting affected.

Production and quality department used the maximum labor, as it required the

labors. Other department apart from production and quality did not require any

labors. The maximum labor requirement was in the department of production as it

had many labor works. The cables are assembled in drums this drum is moved from

one end of the company to the other for various multi stage process. This

movement of drums is the most excruciating work in the cable industry. As for

quality and testing department there were various processes where cables are

needed to worked upon to prepare for testing, hence it also required huge

amount of labor work. Hence these two different departments were facing the

problem of labors. The HPTs and the engineers were so fed up with the labors

that they did not want to work for this company. They were abandoning the ship

at the first chance they got. Due to various reasons the top management of the

company remained in the darkness as proper complaints did not reach them via

proper channels in proper time. Due to heated and angry environment the workers

did not listen to the instructions of the HPTs and engineers properly. They had

the mental notion of the HPTs do not understand their problem then they will

not obey the instruction of the HPTs, this evasive mentality caused various

problems. Another factor was absenteeism among the labors. With lack of

education bad state of living the labors did not come to the manufacturing

plant on a regular basis as they had other works. With less man power and

inefficient worker, the targets were suffering a lot as well as the revenue of

the company. Due to this hit in the revenue system the pressure from the top

management was increasing day by day. Increasing pressure meant increasing

targets and the cycle got intensified in this way.

As this circle of miscommunication and the

environment of dissatisfaction increase day by day the attrition rate

increased. This issue got escalated when some Labor provider providers were

decreasing due to crop season. The labors were part famer as the crop season

started the farm work also started. The absenteeism increased and the labors

started doing more over times. As a addition to this the labor bill was

increasing on the company as over time were increasing. Hence this issue needed

to address at the earliest. Dheeraj had an option to change the Labor provider

altogether and to talk to the Labor provider and try to find a solution with

the help of the following Labor provider.

Comments

Post a Comment